Meritor Inc. will supply front- and rear-drive axles to Terex Advance Mixer under a standard position agreement. Earlier installations make way for a seamless transition of incorporating the Meritor components into Terex Advance’s specs.

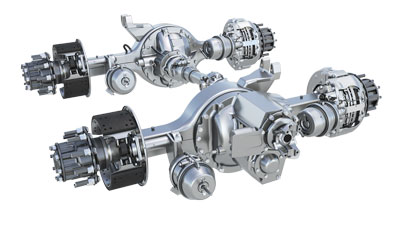

Under the agreement, Meritor will supply its MX23-810 front-drive axle with standard EX+ air disc brakes, and MX23-160 front-drive axle and RT46-160 rear-drive axle, both with drum brakes or optional EX+ air disc brakes. The MX23-810 is an optional replacement for the MX23-160 for those Terex Advance customers who prefer the lighter-weight, improved safety and reduced maintenance costs that come along with disc brakes when compared to drum brakes.

“With this agreement, we’ll deliver proven drivetrain solutions for Terex concrete mixers, expanding our strategic relationship with a company that values safety, quality and customer support,” says Meritor’s Matt Wolfe, vice president of Industrial. “It’s another example of Meritor’s commitment to grow its Industrial business as a key priority within its corporate strategy.”

The MX23-810 was initially developed for mine-resistant ambush-protected (MRAP) military vehicles, and was launched in full production for the commercial industry in 2016. Meritor’s RT46-160 tandem drive axle has been a long-term cornerstone of various commercial markets such as Class 8 on-highway, construction and utility and fire and rescue. Disc brakes were introduced on the RT-160 in 2018 for Terex Advance mixers. — Meritor Inc., Troy, Mich., 248/435-1000; www.meritor.com

XL SPECIALIZED EXPANSION

XL Specialized Trailers, a key player in custom, heavy haul equipment, plans an investment up to $7 million to expand its Manchester, Iowa headquarters and increase production capacity by more than 30 percent. Set to begin by early this year and wrap up by December, construction will add roughly 55,000 square feet to the north side of its current manufacturing footprint. The expansion will also see the addition of 65 new jobs.

“Increasing our space and adding more team members positions us to serve customers better than ever before,” says XL Specialized Trailers President Stuart Sleper. “We will be well positioned for growth in the market and reduce lead times on our products.”

Record 2019 sales allowed the company to power through the Covid-19 pandemic despite what the market indicates as a 45 percent drop in the low-bed trailer industry last year, he adds, noting: “We’re fortunate to have a diversified portfolio in the industries we serve, with some sectors performing better than others. At the moment, we have a backlog and strong order activity. We also are fortunate to have the best dealership network in the industry and a loyal customer following. When the economy bounces back, we’ll be able to take advantage of our expansion in production capacity.” — www.xlspecializedtrailer.com